Backflow Prevention Assemblies

A backflow prevention assembly can actually save lives. As just one example a failed backflow preventer allowed an antifreeze mixture to flow into the potable water system at a Colorado school in 1990. Fortunately no one died but over a half-dozen students had to be hospitalized. So it shouldn’t be surprising that annual testing and certification is required. Otherwise you may face a large fine and/or a water shut-off. Licensed and certified, we provide backflow prevention maintenance, repair, and installation services with an emphasis on both quality and economy.

Sanford & Son plumbing provides professional and affordable backflow services to all Lake Elsinore, Temecula, Murrieta, Sun City, Menifee, Wildomar and surrounding areas.

Exactly What is a Backflow?

Any reversal of the normal direction of flow that allows hazardous water into the drinking water system is a backflow. That can result from the use of pressure-boosting pumps as well as siphoning (negative pressure or vacuum) due to a sudden or heavy use in the distribution system (such as in firefighting). An improper cross-connection can also be called a back flow. The result can be classified as a pollutant (if it doesn’t directly affect human health) or as a contaminant (posing a health hazard). Problem sources include used or stagnant water, fertilizer mixtures, oils, and non-approved water sources.

Backflow Prevention

Quality Service with the best plumbing technicians

Prevention Devices

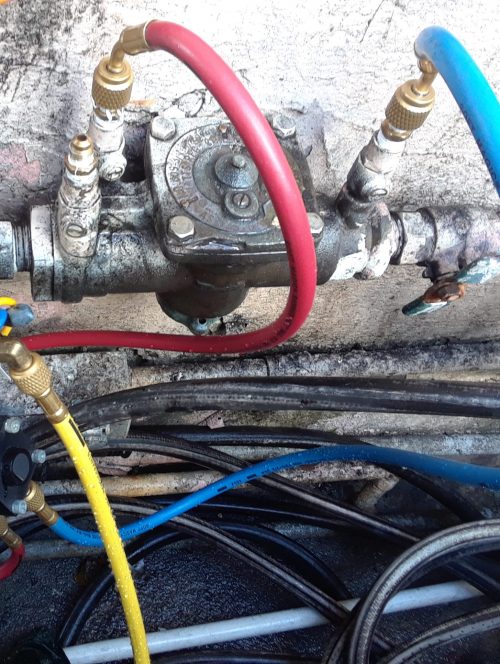

Whenever there’s a potentially dangerous backflow, a backflow prevention assembly is required. That’s been a national requirement since 1974, and each locality has its own codes and ordinances. In general, backflow prevention assemblies are required for all commercial buildings. Residences may be required to have a prevention assembly if they have an on-site well, a booster pump, or other hazard (such as a fertilizer feed on an irrigation system).

The two major types are reduced-pressure principle and double check-valve. The following are more specific device types, roughly in order of maximum to lesser protection.

- RP — Reduced pressure principle. Used in hospitals, industrial plants, and soda fountains.

- RPDA — Reduced pressure detector. Used mostly in fire suppression systems.

- DCDA — Double check detector. For fire protection systems.

- DC — Double check valve. Used primarily in fire sprinkler systems that don’t use toxic fluids.

- SVB — Spill resistant vacuum breaker. Used for ice-makers and other restaurant equipment.

- PVB — Pressure vacuum breaker. Commonly used for irrigation systems.

Each particular make and model must be approved for a particular use.

Installation, Repairs, and Maintenance

Backflow prevention maintenance is usually performed as part of annual testing, and typically involves adjustments. Repairs are most commonly made after a failed test. All installation, repairs, and maintenance must be performed by a licensed and approved plumbing company. New installations must be according to plumbing and local building codes, and the replacement of an existing backflow preventer typically requires a permit.

Testing and Certification

Regulations require safety inspections, testing, and re-certification of all backflow devices annually. More frequent testing may be required for particularly hazardous installations. Testing may be performed only by certified testers with extensive training. And their test instruments must be closely monitored as well as calibrated annually. To meet requirements we also maintain records of all locations and tests along with any repairs performed.

Need Backflow Certification Service?

Call (951) 447-8227